Each type of network requires a fiber optic cable appropriate to the technical, mechanical and environmental conditions of the place where it will be installed. For that reason, you should know what types of fiber optic cables exist and find the ones that best suits your needs.

Fiber optic cable types

Sometimes the appropriated cable can be difficult to choose due to the great diversity of choices and environmental conditions.

For a communications operator, assuming that the fiber is always single-mode, the choice of the fiber optic cable is based on the cable protections and is divided into these types:

Backbone Cable: Works as a mains cable for the network, it must be very robust, be prepared to withstand various types of outdoor environment (water, sun, cold, heat, etc.), and animals (rats, moles, etc.) , in the case of aerial cables, to hunters (anti-ballistic). These are normally high fiber capacity cables (more than 24 fibers) in a loose tube construction.

For duct: These cables must have great resistance to water and to the creation of germs inside. They must have a high tensile strength to be able to be pulled for longer distances.

To bury directly: It does not need as much tensile strength as the conduit cable, but it must have great water resistance and strong anti-rodent protection, usually achieved by a steel shield. This steel shield makes the cable conductive of electrical energy, being necessary that in its installation it is not very close to sources of electromagnetism. For these cases a dielectric cable must be used.

Aerial: The aerial fiber optic cable can be self-supporting with a central strength element to support the entire weight of the cable, or of the figure 8 type where this strength element is external to the fiber cable.

Distribution cable: It is the cable responsible for connecting the backbone cable with the customer’s inboxes. They don’t need as many mechanical protections as Backbone cables but, as they are often outdoors, they need environmental protection.They are low fiber number cable, normally below 24 fibers.

Drop Cable: Connects the distribution box to the customer. It is an indoor cable with light mechanical protection, without the need for special environmental protection. The ITU G657A2 standard is indicated for this section of the network as it allows tighter bending radius in the pipes of the customer installation. It is normally 1 or 2 fiber cable.

Type of fiber

For a local network, in addition to the criteria defined above (mechanical and environmental protections), it is necessary to define the type of fiber to be installed.

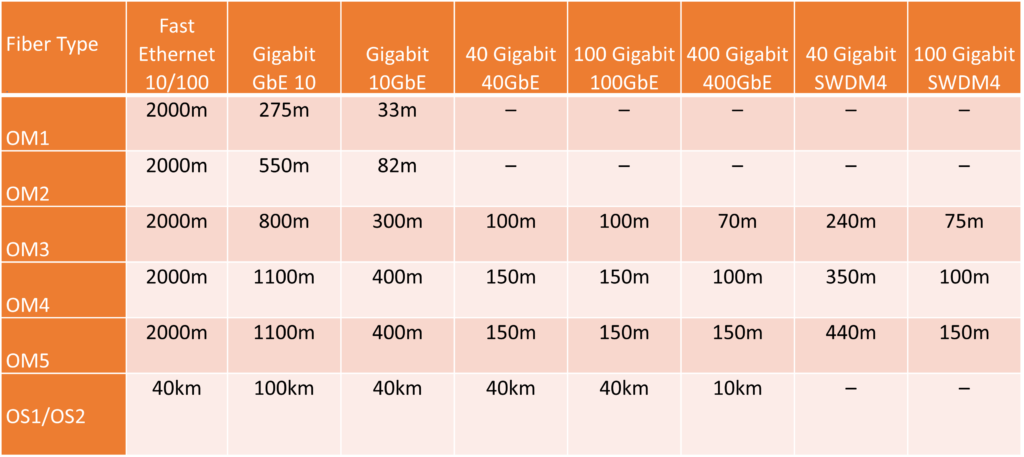

Single-mode fiber has a core of 9 microns and needs a laser emitter. It can carry the optical signal for several kilometers and at great speed. However, the active equipment (lasers) is a little more expensive.

Multimode fiber has a 50 micron core (there is also a 62.5 micron core but practically discontinued), with LED or VCSEL emitter. It can carry the optical signal for a few kilometers at low speed or for a few meters at higher speed.

Based on this table and on the network needs, you can now choose the appropriate fiber optic cable type for the installation, always leaving room for future expansion. Considering the small difference in material costs between single-mode and multi-mode, almost every installation justifies being single-mode.

Related articles: 4 Features to Look for in an Optical Distribution Frame

Top!

Thank you, Sandra Turpin!

It’s interesting to know about fiber optic cables and how they’re classified. My brother’s interested in installing fiber optic cables in his new house, and since he’s always been a curious person, I think he’d be interested in reading your article. Thanks for the information on what we must consider when choosing fiber optic cables.