Passive Optical Splitters are the components that split the fiber and its signal. These are completely passive networking components, meaning they require no power, no climate control, and no maintenance whatsoever.

A signal from the Aggregation Switch is sent along a run of fiber. When it reaches a Passive Optical Splitter, mirrors and glass in the component split the light into two, or three, or more fiber strands.

The splitter uses the optical power of the incoming signal to equally divide the light between multiple output fibers. The splitter is used in many applications, such as connecting multiple optical receivers, distributing signal to multiple locations, or connecting a single transmitter to multiple receivers.

Fiber optics have revolutionized the telecommunications industry in the past few decades. Optical splitter has played an important role in passive optical networks (like EPON, GPON, BPON, FTTX, FTTH, etc. – types of PONs) by allowing a single PON interface to be shared among many subscribers.

Understanding Fiber Optic Splitters

Passive optical splitters are a cost-effective and reliable solution for many fiberoptic applications. Fiber optic splitter, also referred to as optical splitter, fiber splitter or beam splitter, is an integrated waveguide (they provide wide bandwidth and ensure the least amount of loss in a high-frequency application) optical power distribution device that can split an incident light beam into two or more light beams, and vice versa, containing multiple input and output ends.

Optical fibers represent a special kind of optical waveguide. A waveguide is a material structure that guides light, i.e., lets it propagate while preventing its expansion in one or two dimensions. Fibers are waveguides that guide in two dimensions and can effectively be used as flexible pipes for light.

Types of Fiber Optic Splitters

The two most common types of fiber optic splitters are FBT (Fused Biconical Taper) and PLC (Planar Lightwave Circuit) splitters:

- FBT splitters are made by fusing and stretching two or more fibers together and are relatively simple and inexpensive to manufacture. However, they are limited in terms of the number of splits they can support, typically up to 1:32.

- PLC splitters, on the other hand, use a flat waveguide made of silica or other materials to split the signal. They are more complex to manufacture than FBT splitters, but they can support a larger number of splits, typically up to 1:64 or higher. PLC splitters are also more reliable and offer better performance in terms of insertion loss and wavelength uniformity.

Fiber optic splitters come in different shapes and form factors, depending on the specific application and installation requirements. The most common shapes for fiber optic splitters include:

Box-type Splitter:

This is a type of splitter that is housed in a rectangular box, typically made of plastic or metal. The box contains the splitter components and is designed to be mounted on a wall or placed in a rack or cabinet.

Module-type Splitter:

This is a type of splitter that is designed to be installed inside a fiber optic patch panel or enclosure. The splitter components are contained in a module that can be easily inserted or removed from the patch panel or enclosure.

Bare fiber Splitter:

This is a type of splitter that does not have an outer protective housing or enclosure. Instead, the splitter components are exposed and are typically spliced directly onto the incoming and outgoing fiber optic cables.

Rack-mount Splitter:

This is a type of splitter that is designed to be installed in a standard 19-inch equipment rack. The splitter components are housed in a metal enclosure that can be easily mounted in the rack along with other networking equipment.

Tube-type Splitter:

This is a type of splitter that is housed in a cylindrical tube, typically made of plastic or metal. The tube contains the splitter components and is designed to be mounted on a wall or placed in a splice tray.

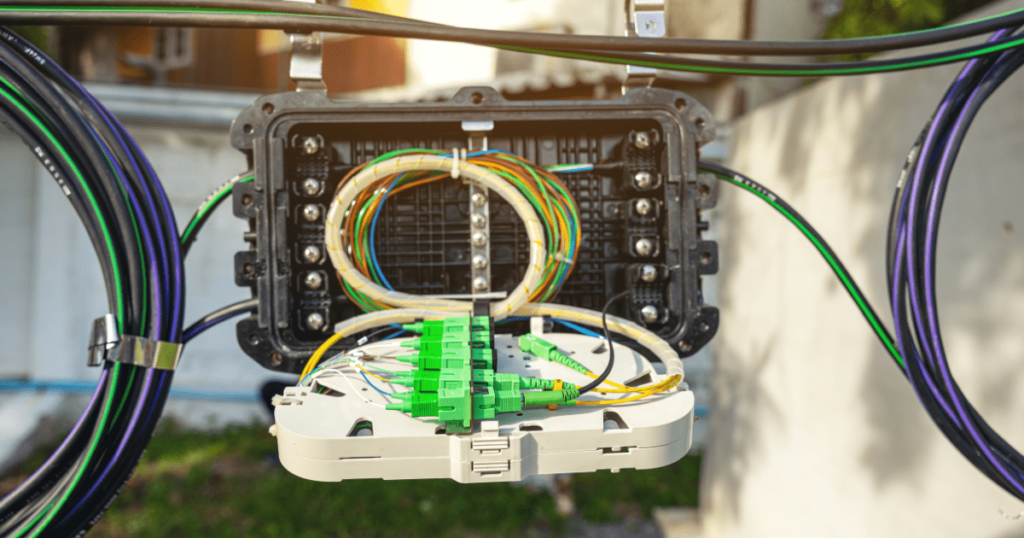

In addition to these common shapes, there are also specialized types of fiber optic splitters that are designed for specific applications or installation requirements. For example, there are splitters that are designed for outdoor use and are ruggedized to withstand harsh weather conditions, as well as splitters that are designed for use in high-density data centers (Plug-in modules) or other environments where space is at a premium.

Applications of Fiber Optic Splitters

PLC splitters are frequently used in optical access networks to provide high-speed internet connectivity to several clients. They provide end users with high-speed and dependable connectivity and are perfect for FTTH (Fiber to the Home) and FTTB (Fiber to the Building) applications. FTTH mainly uses PON network technology, which requires many low-cost optical splitters.

PLC splitters have two different distribution modes in the FTTH network: centralized distribution and cascaded distribution. In PON networks, PLC splitters are usually installed between an Optical Line Terminal (OLT) and an Optical Network Unit (ONU) or Optical Network Terminal (ONT) near the end user. The input end of the PLC splitter is connected to the optical fiber link of the OLT in the central office (CO), and multiple optical signals are split and transmitted to the end users of the optical network.

PLC fiber splitters are frequently used in data center networks to distribute fast data to numerous servers and storage devices. This makes it possible for data centers to efficiently handle high volumes of data traffic, resulting in quick and seamless data transfer.

Key Considerations

When working with this type of telecom equipment, there are some factors that you should have in consideration.

Besides the production process of these two types of splitters being different there are also some performance differences, namely:

- Working wavelength:

FBT only supports 3 wavelengths of 850nm, 1310nm and 1550nm and cannot work at other wavelengths. PLC is between 1260nm and 1650nm and the wavelength can be adjusted to support more application requirements.

- Spectral Ratio (Ratio of Input Signal to the Output Signal):

FBT maximum 1:32 but offers variability and supports customization such as 1:3, 1:7. 1:11 ratios. PLC is as high as 1:64 and provides higher reliability.

- Spectroscopy Uniformity:

The larger the splitting ratio, the worse the uniformity, which affects the transmission distance.

FBT is made of multiple 1×2 connections, lacking in signal management and unable to achieve uniform splitting. PLC can achieve equal ratio uniform splitting.

- Failure Rate:

FBT for greater splitting ratios, the failure rate increases exponentially. PLC failure rate is much less due to the ability to safely add greater splitting ratios.

- Temperature:

Temperature is a key factor affecting insertion loss of optical devices.

FBT has a temp working range of -5º~75ºC. PLC has a wider and stable range of -40º~85ºC which in extreme environments also maintains good performance.

Future of Fiber Optic Splitters

Fibre optics have revolutionized the telecommunications industry in the past few decades, with PLC splitters as a key component of passive optical networks (PON) that make fiber-to-the-home (FTTH) connections possible.

While PLC splitters are typically symmetric, meaning they divide optical signals evenly between output ports, the less typical asymmetric PLC splitters have drawn the attention of industry players, due to the several appealing advantages for end-users, including installation, and other applications.

Asymmetric PLC splitters can be used in distributed splits where the splitter is located closer to the end-user, or for example in a daisy-chain architecture, where multiple splitters are connected in series to divide the signal unevenly. This can be particularly useful in FTTH deployments, where the cost of running fiber to individual households can be reduced by using a daisy-chain architecture.

Lee Jin, R&D Director for Ensure, explains, “using the example of the daisy-chain architecture, the exclusivity of the design and product give producer and client the first-mover advantage with an optimized bespoke design that competitors in the market do not have access to, or the ability to copy in a timely manner”.

Carlos Barragan, International Business Director for Ensure, expands, “at present we are one of the few PLC wafer & chip manufacturers with the advanced technology and equipment required to do such specialized customizations. Given our years’ experience and dedication to providing premium quality, when it comes to scaling up operations based on market or customer demands, we’re always ready to produce the necessary capacity and quality required to advance our client’s networks exponentially” – and advance it does!

The advantages of asymmetric PLC splitters for end-users include greater flexibility in configuring networks, lower deployment costs, reduced set-up time, and improved monitoring capabilities. For installation, the specialized splicing required for asymmetric PLC splitters can be a disadvantage, but this is offset by the flexibility and monitoring capabilities of the splitter.

The asymmetric PLC splitter represents an important piece of the puzzle for creating such benefits, therefore it is equally important to ensure that the quality, reliability, and longevity of the splitter will allow it to meet all expectations.

The question is, how common is it to find a reliable manufacturer proficient in customisation that can supply these sought after components?

As an advanced PLC manufacturer and leader in photonics market for the past 20+ years, Ensure’s obsession with premium quality manufacturing, testing, and inspection processes sets their PLC splitters apart from the competition. Each one of their PLC splitters is carefully manufactured in-house with meticulous control of the entire production chain, ensuring the most reliable connectivity is guaranteed.

Conclusions

In the fast-paced world of modern telecommunications, the efficient transmission of data is crucial. Fiber optic technology has revolutionized the industry, offering high-speed, long-distance communication capabilities. Among the essential components within fiber optic networks, fiber optic splitters play a pivotal role in ensuring the smooth flow of information.

- Enabling Efficient Network Expansion:

Splitters empower network operators to efficiently accommodate the growing demand for bandwidth without the need for extensive rewiring.

- Extending Network Reach:

In telecommunications, it is often necessary to transmit data over long distances without losing signal quality. With the use of splitters, network operators can effortlessly deploy fiber optic connections to multiple locations, such as homes, businesses, and data centers, while maintaining high-speed and reliable communication.

- Ensuring Flexibility and Scalability:

Fiber optic splitters offer remarkable flexibility and scalability for network deployments. They allow for the creation of various network architectures, such as point-to-point or point-to-multipoint configurations, to suit specific requirements.

Splitters can be installed in cabinets, distribution boxes, or even directly on the fiber optic cable, providing a versatile solution that adapts to diverse networking scenarios. This flexibility makes fiber optic splitters ideal for accommodating future network expansions and upgrades.

- Preserving Signal Integrity:

Signal quality is paramount in telecommunications, and fiber optic splitters excel in preserving the integrity of the optical signal. With their low insertion loss and minimal added attenuation, splitters ensure minimal signal degradation, enabling efficient transmission over long distances. By maintaining signal quality, splitters contribute to reliable and high-performance communication, satisfying the demands of modern applications such as video streaming, cloud computing, and real-time data transfer.

When considering network deployments, it is essential to seek expert guidance to determine the optimal splitter solutions for specific requirements. Experienced professionals can assess network designs, recommend appropriate splitter types, and ensure the smooth integration of splitters within the infrastructure.

By harnessing the power of fiber optic splitters, telecommunications providers can build robust and future-proof networks to meet the ever-growing demands of our interconnected world.

Related articles: Telecom Cabinets and Racks: Know their Features and Main Characteristics