Fiber optic connectors are common in FTTH (Fiber to the Home) communication networks and the ever expanding 5G infrastructure but are also tapping into opportunities in the power plant, wind turbines and industrial automation industries as well as the ever-increasing usage in enterprise and data center solutions. Fiber optic connectors market are relying on the rapidly growing 5G networking infrastructure to keep businesses expanding.

Know how to identify them

SC – (Standard/Subscriber Connector)

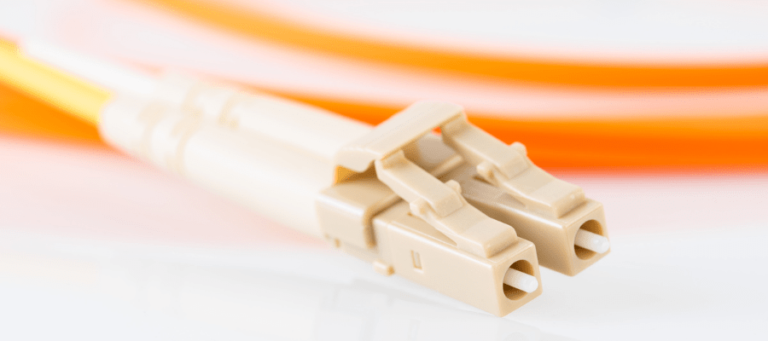

LC – (Lucent Connector)

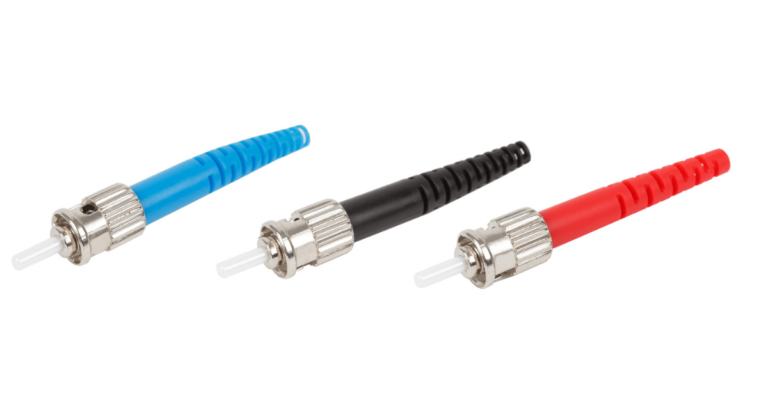

ST – (Straight Tip)

Developed by AT&T. Uses a bayonet fitting and cannot be terminated with an angle polish, limiting its use in single mode & FTTH applications. The quick connecting bayonet has its advantage in military applications but is predominantly used in corporate and multi-mode networks.

FC – (Ferrule Core)

Was the first optical fiber connector to use a “physical contact polish” ceramic ferrule. The connector end face relies on an alignment key for correct insertion and is then tightened into the adaptor/jack using a threaded collet.

Despite the additional complexity both in manufacturing and installation, it’s still the connector of choice for precise measuring equipment such as OTDRs.

E2000 – (Latched Push-pull connectors with automatic metal shutter)

Manufactured under license from Diamond SA. It perfectly centers the fiber core on the axis ferrule that reduces insertion loss to a minimum using active core technology. Additionally, with coloured and/or mechanically coded housing frames and latches provide clear and secure identification of the transition lines.

MTP/MPO – (Multi Fiber Push-on/Pull-off)

Invented by NTT in 1980. Used extensively in high density patch environments such as datacenters but starting to appear in FTTH applications. Ferrule alignment is achieved through high precision guide pins.

Available in 4,8 and 12 fiber versions, PC and APC finishes, and support both multimode and single mode applications. Premium optical performance (low IL and high RL) is a result of advanced polishing technology.

Now that you know more about fiber optic connectors discover a specialized marketplace in telecommunications where you will find all connectors. Check them here.

Related articles: Differences Between Fiber Pigtails and Fiber Patch Cords