Well cleaned fiber optic connectors are a must if you want your networks to work without any issue. Splicers and field engineers usually don’t include a cleaning routine, however it’s important to clean fiber connectors especially in specific stages.

With this article you will find out why is so important to keep a cleaning routine, how to check connectors, when to clean them and which tools you should use to do it.

Why is it important to clean fiber connectors?

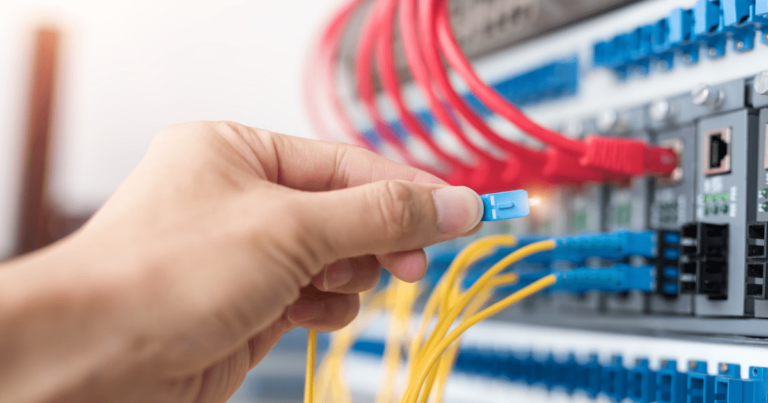

When one connector is mated to another, both connectors should always be properly cleaned and inspected since deploying fiber in the field is often a dirty job.

According to the FTTH Council Europe Handbook, “A dirty ultra polish connector with a normal return loss of >55dB can easily have >45dB reflectance if it is not cleaned properly. Similar comparisons can be made with angled polish connectors. This can greatly affect system performance, especially in CATV applications where carrier-to-noise ratios (CNR) are directly related to signal quality.”

Main reasons to clean fiber connectors before installation

Equipment may fail

Dirt in connectors can cause huge damage in networks equipment, adding more costs and time consumption since the equipment will need to be replaced.

Signal failure

Fiber networks work with light pulses that need to travel from the beginning to the end of the cable with sufficient power to be measured. If the network is contaminated with dirt, it will block the signal resulting on power reduction and loss of efficiency.

When to inspect and clean connectors

As said before, the cleaning and inspection of fiber connectors should be part of a routine to avoid future problems in networks. On FTTH Council Europe Handbook are shared the main stages where you should clean fiber connectors:

- after installation

- before testing

- before connecting

- any time a connector is manipulated

How to check connectors

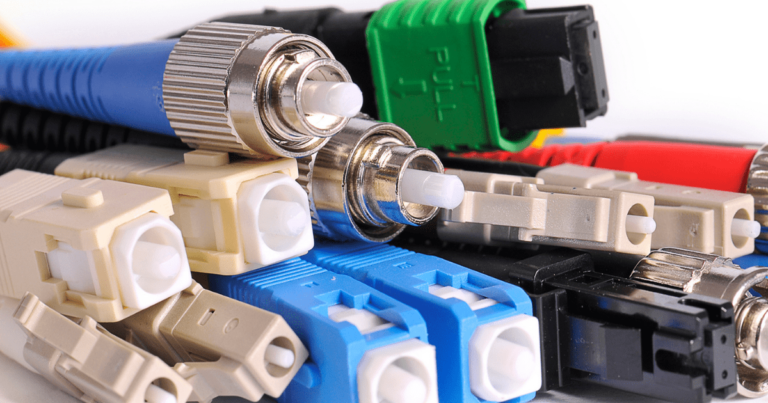

When the time to inspect connectors arrives, you should have the right material to make sure you are able to make a properly inspection of the connector end face.

Although existing many types of inspection tools in the market, there are two main categories. The fiber inspection probes or optical microscopes, where the last ones are most recommended.

Cleaning tools and procedures

The tools that are used to inspect connectors must be made to check dirt at a microscopic level because this dirt is the most dangerous for your equipment. So, it is better to make sure that you clean fiber connectors the best way possible or later you may find problems in the network.

All the team should be aware of the risks of not having a cleaning routine for connectors and should be properly trained with the right procedures to do it.

Below we will share two methods of cleaning connectors:

Dry Cleaning

In this method, you should clean fiber connectors with dry cleaning wipes. This is a simple method that should be made with lots of detail so that no dust is left.

Don’t forget to never leave cleaning wipes open if you’re not using. Every time you open the package of cleaning wipes, it’s an opportunity for contamination.

Damp cleaning

Through damp cleaning, you should also use cleaning wipes for this process. Another option is to get pre-soaked wipes that should have the same care as dry wipes, to not be contaminated.

If you have more questions about the best way to clean connectors, you should check the IEC 6100-3-35 standard, that provides guidelines size and amount of dirt or other type of contaminators that can be accepted for connectors.

Related articles: Fiber optic products manufacturers in Europe you should definitely know